Fiber Cement Siding Versus Vinyl Siding A Homeowners Guide

Fiber cement siding versus vinyl siding: Choosing the right exterior cladding for your home is a big decision, impacting both aesthetics and long-term costs. This guide dives into a head-to-head comparison, exploring durability, maintenance, cost, and environmental impact to help you make an informed choice. We’ll unpack the pros and cons of each, examining factors like lifespan, resistance to damage, and the overall look and feel they bring to a house. Get ready to weigh the options and find the perfect siding for your needs!

Ultimately, the “best” siding depends on your priorities. Are you prioritizing low maintenance and longevity, or is budget your primary concern? Understanding the nuances of each material—from initial installation costs to long-term upkeep—will empower you to make a decision that aligns perfectly with your home and your lifestyle.

Cost Comparison

Choosing between fiber cement and vinyl siding involves a careful consideration of upfront and long-term costs. While vinyl often boasts a lower initial investment, fiber cement’s durability can lead to significant savings over the lifespan of your home. Let’s break down the financial aspects of each option.

Initial Cost Comparison

The initial cost of siding installation includes both materials and labor. Fiber cement generally commands a higher price tag due to its superior strength and longevity, while vinyl siding offers a more budget-friendly starting point. However, the price difference can vary depending on the chosen quality and style of siding. The following table provides average cost estimates per square foot in the United States, keeping in mind that these are approximations and can fluctuate based on location, labor rates, and specific product choices.

| Siding Type | Low-Quality (Cost/sq ft) | Medium-Quality (Cost/sq ft) | High-Quality (Cost/sq ft) |

|---|---|---|---|

| Vinyl | $3 – $5 | $5 – $8 | $8 – $12 |

| Fiber Cement | $7 – $10 | $10 – $15 | $15 – $25 |

Long-Term Cost Implications

Understanding the long-term cost implications is crucial for making an informed decision. While vinyl siding might seem cheaper initially, factors like maintenance, repairs, and potential premature replacement can significantly impact your overall expenses over 20 years.

- Fiber Cement: Fiber cement siding is known for its exceptional durability and resistance to damage from weather, insects, and fire. Maintenance is minimal, typically involving occasional cleaning. While repairs might be more expensive per incident due to the material’s strength, the infrequency of needed repairs translates to lower overall costs over the long term. A properly installed fiber cement siding system can easily last 50 years or more, significantly reducing the likelihood of needing complete replacement within a 20-year timeframe. For example, a homeowner in a hurricane-prone area might find the higher initial cost of fiber cement worthwhile to avoid costly repairs or replacement after a storm.

- Vinyl Siding: Vinyl siding is relatively inexpensive to install, but it’s susceptible to damage from impact, extreme temperatures, and UV radiation. This can lead to more frequent repairs, such as replacing damaged panels. While individual repairs might be less costly than those for fiber cement, the cumulative cost of these repairs over 20 years can add up. Furthermore, vinyl siding typically needs replacing every 15-20 years, incurring a substantial cost for a complete re-siding project. A homeowner in a sunny climate, for instance, might find themselves dealing with faded or cracked vinyl panels sooner than expected, leading to early replacement costs.

Durability and Longevity

Choosing between fiber cement and vinyl siding often comes down to how long you want your home’s exterior to last and how well it can withstand the elements. Both options offer decent lifespans, but their performance varies significantly depending on the climate and the level of maintenance they receive. This section will delve into a detailed comparison of their durability and longevity.

Fiber cement and vinyl siding react differently to various weather conditions and potential damage. Understanding these differences is crucial for making an informed decision that aligns with your home’s location and your long-term goals.

Fiber Cement and Vinyl Siding Lifespan Under Various Weather Conditions

The lifespan of both fiber cement and vinyl siding is significantly impacted by weather. Extreme temperatures, high humidity, and strong winds all contribute to wear and tear. Let’s examine how each material fares under these conditions.

- Extreme Heat: Fiber cement generally handles extreme heat better than vinyl. While it might experience some minor expansion and contraction, it’s less prone to warping, melting, or significant color fading compared to vinyl. Vinyl, especially in intense sun, can become brittle and prone to cracking.

- Extreme Cold: Both materials can withstand freezing temperatures, but vinyl can become more brittle in extreme cold, making it more susceptible to cracking or damage from impacts. Fiber cement remains more stable and less likely to suffer damage from cold weather.

- High Humidity: Fiber cement is inherently more resistant to moisture damage than vinyl. While properly installed vinyl siding can resist moisture, prolonged exposure to high humidity can lead to mold and mildew growth behind the siding. Fiber cement’s composition makes it less susceptible to these issues.

- Strong Winds: Proper installation is key for both materials. However, fiber cement’s greater strength and weight give it a significant advantage in resisting high winds. Vinyl siding, being lighter, is more prone to damage from strong winds, potentially leading to warping or detachment.

Resistance to Impact, Scratches, and Dents

The resistance of each siding material to physical damage is another crucial factor in determining longevity. Fiber cement’s inherent strength makes it far superior to vinyl in this regard. However, even fiber cement can be damaged with enough force.

| Siding Type | Impact Resistance | Scratch Resistance | Dent Resistance |

|---|---|---|---|

| Fiber Cement | High; resists damage from hail and other impacts better than vinyl. | Moderate; can be scratched, but scratches are less noticeable than on vinyl. | Moderate; dents are possible with significant force, but less likely than with vinyl. |

| Vinyl | Low; easily damaged by hail, impacts from falling branches, or strong objects. | Low; scratches are easily visible and difficult to repair. | Low; dents easily occur with relatively minor impacts. |

Maintenance and Repair

Choosing between fiber cement and vinyl siding involves considering long-term maintenance and repair needs. Both materials require different approaches, and understanding these differences is crucial for making an informed decision. While both can last for many years, the frequency and cost of maintenance and repairs vary significantly.

Regular maintenance is key to extending the lifespan of any siding. Neglecting maintenance can lead to premature deterioration and costly repairs down the line. The type of siding you choose will directly impact the time and money you’ll spend on upkeep.

Fiber Cement Siding Maintenance

Fiber cement siding is known for its durability, but it still requires some maintenance to keep it looking its best and performing optimally. A regular cleaning schedule and occasional repairs are necessary.

- Annual Cleaning: Wash your fiber cement siding annually with a garden hose and a soft-bristled brush. Use a mild detergent if needed, but avoid harsh chemicals that can damage the surface. Rinse thoroughly to prevent staining.

- Caulk Inspection and Repair: Regularly inspect the caulking around windows and doors. Reapply caulk as needed to prevent water damage. This is particularly important in areas with extreme temperature fluctuations.

- Repairing Minor Damage: Small chips or cracks can be repaired using a patching compound specifically designed for fiber cement. Follow the manufacturer’s instructions carefully.

- Painting (if applicable): If your fiber cement siding is painted, repaint every 5-10 years, depending on the paint type and exposure to the elements. This will protect the siding from moisture and UV damage.

Vinyl Siding Maintenance

Vinyl siding is generally considered low-maintenance, but it still requires periodic cleaning and occasional repairs to maintain its appearance and functionality.

- Annual Cleaning: Wash vinyl siding annually with a garden hose and a soft-bristled brush. A mild detergent can be used for stubborn stains, but avoid harsh chemicals or abrasive cleaners. Again, thorough rinsing is essential.

- Inspection for Damage: Regularly inspect the siding for cracks, dents, or loose panels. Address any issues promptly to prevent further damage.

- Repairing Minor Damage: Small dents or scratches can often be repaired by gently heating the affected area with a hairdryer. For more significant damage, replacing the affected panel might be necessary.

Repair Costs Comparison

The cost of repairing fiber cement and vinyl siding varies depending on the extent of the damage and the labor costs in your area. However, some general estimates can be provided.

| Repair Scenario | Fiber Cement Cost (USD) | Vinyl Siding Cost (USD) | Notes |

|---|---|---|---|

| Replacing a single damaged panel | $50 – $200 | $20 – $100 | Costs vary significantly based on panel size and labor. |

| Repairing minor cracks or chips | $20 – $50 (materials) | $10 – $30 (materials) | Labor costs are minimal for minor repairs. |

| Caulk repair around windows/doors | $10 – $30 (materials and labor) | $10 – $30 (materials and labor) | This is a relatively inexpensive repair for both materials. |

| Repainting (fiber cement only) | $1,000 – $3,000 (for an average-sized house) | N/A | Cost depends on house size and paint quality. |

Aesthetic Appeal and Design Options

Source: urbanexteriorsgb.com

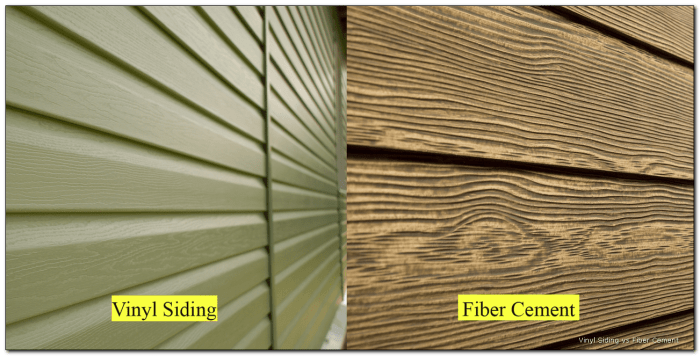

Choosing between fiber cement and vinyl siding often comes down to personal preference, as both offer a wide variety of styles and colors to complement any home. However, their capabilities in mimicking other materials and achieving specific aesthetic looks differ significantly. This section will explore the design options available for each siding type.

Both fiber cement and vinyl siding offer extensive color palettes and textures, allowing for a high degree of customization in your home’s exterior. However, the range and realism of these options vary between the two materials.

Fiber Cement Siding Design Options, Fiber cement siding versus vinyl siding

Fiber cement siding excels at mimicking the look of natural materials. Its versatility allows for a broad range of aesthetic choices, from classic to contemporary.

- Colors: Fiber cement siding boasts a wide array of colors, often offering more nuanced and deeper shades than vinyl. Many manufacturers provide custom color matching options for a truly unique look.

- Textures: Fiber cement can convincingly replicate the texture of wood shakes, clapboard, and even stone. The deep grooves and realistic grain patterns add depth and visual interest.

- Styles: From traditional lap siding to more contemporary styles like board and batten, fiber cement offers a diverse selection to match various architectural designs. It can also be cut and shaped to create intricate details and custom designs.

Fiber cement’s ability to mimic natural materials is remarkable. Its texture and color variations allow it to convincingly replicate the look of cedar shake siding, creating a rustic charm without the high maintenance of real wood. Similarly, certain fiber cement products can accurately portray the rugged texture and subtle color variations of natural stone, lending a sophisticated and elegant feel to a home’s exterior. The realistic appearance of these materials elevates the home’s curb appeal significantly.

Vinyl Siding Design Options

Vinyl siding is known for its affordability and wide range of colors, but its ability to convincingly replicate natural materials is less impressive than fiber cement.

- Colors: Vinyl siding comes in a vast array of colors, often including bright, bold options. However, the colors may appear less rich and natural compared to fiber cement.

- Textures: While vinyl can simulate wood grain or a slightly textured surface, the realism is often less convincing than fiber cement. The textures tend to be more uniform and less varied.

- Styles: Vinyl siding is primarily available in traditional lap siding styles, although some manufacturers offer variations like shake or shingle styles. The design options are generally less diverse than those offered by fiber cement.

Vinyl siding’s imitation of natural materials is often less successful than fiber cement. While it can provide a wood-like appearance, the texture is typically smoother and less nuanced, lacking the depth and variation of real wood or even high-quality fiber cement. Attempts to mimic stone often result in a somewhat plastic-looking finish. However, its advantage lies in the sheer variety of bright, solid colors that are available, providing a wide range of options for modern or brightly colored homes.

Environmental Impact: Fiber Cement Siding Versus Vinyl Siding

Source: sidingauthority.com

Choosing between fiber cement and vinyl siding involves considering their respective environmental footprints. Both materials have impacts throughout their lifecycles, from raw material extraction and manufacturing to installation and eventual disposal. Understanding these impacts can help homeowners make informed decisions aligned with their environmental values.

Let’s delve into a comparison of the environmental impacts of fiber cement and vinyl siding, focusing on manufacturing, installation, and disposal.

Manufacturing Processes and Associated Emissions

The manufacturing processes for fiber cement and vinyl siding differ significantly, leading to variations in their environmental impact. Fiber cement production generally requires more energy and results in higher greenhouse gas emissions due to the cement component’s high energy intensity in the manufacturing process. However, fiber cement utilizes naturally occurring materials like cement, sand, and cellulose fibers, while vinyl siding relies heavily on petroleum-based polymers. The extraction and processing of these polymers contribute significantly to greenhouse gas emissions and air pollution.

- Fiber cement siding manufacturing often involves higher energy consumption and associated greenhouse gas emissions compared to vinyl.

- Vinyl siding manufacturing relies heavily on fossil fuels, contributing to air and water pollution.

- The transportation of raw materials and finished products contributes to the overall carbon footprint of both siding types.

Installation and Waste Generation

Installation of both siding types generates waste, though the types and quantities differ. Fiber cement siding, being heavier and more brittle, can result in more material waste during cutting and installation. Vinyl siding, while easier to handle, often requires more pieces for installation, potentially generating more packaging waste.

- Fiber cement installation may generate more material waste due to breakage and cutting.

- Vinyl siding installation typically involves more packaging waste.

- Both installation processes can generate construction debris that requires proper disposal.

Recyclability and Sustainability

The recyclability and overall sustainability of fiber cement and vinyl siding vary considerably. While some progress is being made in vinyl recycling, it remains a significant challenge due to the complexity of the material’s composition. Fiber cement, while not typically recycled in the same way as other materials, its components are naturally occurring and generally less harmful to the environment in landfills.

Comparative Table: Recyclability and Sustainability

| Feature | Fiber Cement Siding | Vinyl Siding | Notes |

|---|---|---|---|

| Recyclability | Limited; components may be salvaged or used in other applications. | Low; specialized facilities are needed, and the process is not widely available. | Recycling rates are low for both materials. |

| Sustainability | Uses naturally occurring materials; generally less harmful in landfills. | Relies on petroleum-based polymers; contributes to landfill waste and pollution. | Consider the embodied energy and lifecycle emissions. |

| Disposal | Can be disposed of in landfills, though some components may degrade slowly. | Persists in landfills for a long time, contributing to pollution. | Landfill space is a finite resource. |

| End-of-Life Options | Limited options for reuse or recycling. | Limited options for reuse or recycling; some companies offer take-back programs. | Explore potential options for reuse or repurposing before disposal. |

Installation Process

Source: americanroofingco.com

Choosing between fiber cement and vinyl siding involves understanding the installation process. Both have their own set of requirements, impacting project timeline and overall cost. The differences primarily lie in the materials’ handling, the tools needed, and the level of expertise required for a professional finish.

Installation time and complexity differ significantly between fiber cement and vinyl siding. Fiber cement is generally more labor-intensive and time-consuming, requiring more specialized skills and tools. Vinyl, on the other hand, is often considered faster and easier to install, making it a more DIY-friendly option.

Installation Time and Complexity Comparison

The following bullet points highlight the key differences in installation time and complexity between fiber cement and vinyl siding installations for a typical single-family home.

- Fiber Cement: Installation is typically slower due to the heavier weight of the panels, the need for precise cutting and fitting, and the potential for more complex fastening procedures. Expect a longer project timeline, potentially requiring multiple skilled installers and more time for preparation and cleanup.

- Vinyl Siding: Installation is generally faster and simpler. The lighter weight and easier-to-handle panels allow for quicker installation. Fewer specialized tools are needed, and the process is often straightforward enough for experienced DIYers to manage.

Tools and Skills Required

The tools and skills required for each siding type vary considerably. Fiber cement demands more specialized tools and a higher level of skill, while vinyl siding installation is more accessible to those with basic DIY skills.

| Tool/Skill | Fiber Cement | Vinyl Siding | Description |

|---|---|---|---|

| Cutting Tools | Circular saw with a diamond blade, specialized scoring tools | Hand saw, utility knife | Precise cuts are crucial for fiber cement, requiring specialized tools to avoid cracking. Vinyl can be cut more easily with standard tools. |

| Fastening Tools | Nail guns (capable of driving large nails), impact driver | Nail guns (for thinner nails), hammer | Fiber cement requires stronger fasteners and tools capable of driving them effectively into the substrate. Vinyl siding uses smaller nails and can be installed with a hammer or less powerful nail gun. |

| Measuring and Marking Tools | Measuring tape, level, chalk line, speed square | Measuring tape, level, chalk line | Accurate measurements are essential for both, but the heavier weight and less flexible nature of fiber cement necessitate more precise marking and layout. |

| Safety Equipment | Safety glasses, dust mask, gloves, hearing protection | Safety glasses, gloves | Fiber cement cutting generates dust and requires more robust safety precautions compared to vinyl. |

| Skills | Experience with power tools, precise cutting and measuring, knowledge of building codes and construction practices | Basic DIY skills, ability to follow instructions, understanding of basic construction principles | Fiber cement installation demands expertise in handling power tools and precise cutting techniques. Vinyl siding installation requires less specialized knowledge. |

Fire Resistance and Safety

Source: affordablesidingbc.ca

Choosing siding involves considering not only aesthetics but also the crucial aspect of fire safety. Both fiber cement and vinyl siding offer varying degrees of fire resistance, impacting the safety of your home and its inhabitants. Understanding these differences is essential for making an informed decision. This section compares the fire performance of each material and highlights important safety considerations during installation and in the event of a fire.

Fiber cement siding and vinyl siding exhibit significantly different responses to fire. Fiber cement, a composite material of cement, sand, and cellulose fibers, is inherently more fire-resistant than vinyl. Vinyl, being a thermoplastic polymer, melts and ignites more readily. This difference directly impacts the safety of your home in a fire scenario.

Fire Resistance Ratings

The fire resistance of building materials is often assessed using various standards and tests, resulting in different ratings. While specific ratings can vary depending on the manufacturer and product formulation, fiber cement siding generally achieves higher fire ratings than vinyl siding. Fiber cement siding often meets or exceeds Class A fire ratings in many regional building codes, signifying superior fire resistance. In contrast, vinyl siding typically falls into Class C, indicating a lower level of fire resistance. This means that fiber cement is significantly less likely to contribute to the rapid spread of fire compared to vinyl.

Safety Considerations During Installation

Proper installation practices are crucial for maximizing the fire safety benefits of any siding material.

- Fiber Cement: While generally safer, dust generated during cutting and installation of fiber cement siding can be irritating. Appropriate respiratory protection, such as dust masks, should always be worn. Furthermore, the material’s hardness requires specialized tools and caution to prevent injuries during handling and installation.

- Vinyl Siding: Vinyl siding, while easier to handle, can release harmful fumes when heated or burned. Therefore, adequate ventilation during installation is essential to minimize exposure to these fumes. Additionally, care should be taken to avoid overheating the material during installation, which could potentially cause warping or ignition.

Safety Considerations During a Fire

The inherent fire-resistant properties of each siding material directly impact their behavior during a fire.

- Fiber Cement: Due to its higher fire rating, fiber cement siding is less likely to ignite and contribute to the rapid spread of flames. This provides valuable time for occupants to evacuate and firefighters to contain the fire. However, it’s important to remember that even fire-resistant materials will eventually succumb to intense heat.

- Vinyl Siding: Vinyl siding’s low fire rating means it can melt, ignite easily, and contribute to the rapid spread of fire. This poses a significant risk to the safety of building occupants and firefighters. The melting vinyl can also release toxic fumes, further exacerbating the dangers of a fire.

Conclusion

Choosing between fiber cement and vinyl siding requires careful consideration of various factors. While vinyl offers affordability and ease of installation, fiber cement boasts superior durability and longevity. Weighing the initial cost against long-term maintenance and repair expenses, along with aesthetic preferences and environmental impact, will guide you towards the best option for your home. Remember to consult with a qualified contractor to get personalized advice and accurate cost estimates for your specific project.

FAQ Resource

Can I paint fiber cement siding?

Yes, fiber cement siding can be painted, but it requires proper preparation and a paint specifically designed for exterior use on this material.

How does vinyl siding handle hail damage?

Vinyl siding can dent or crack from hail, depending on the size and impact force. Larger hail can cause significant damage.

What’s the warranty typically offered on each type of siding?

Warranties vary greatly by manufacturer, but vinyl siding warranties often cover 20-30 years, while fiber cement warranties can range from 15-50 years depending on the brand and specific product.

Does fiber cement siding fade in the sun?

Fiber cement siding is more resistant to fading than vinyl, but it can still fade slightly over time, especially if not properly painted and maintained.

Is professional installation necessary for both types of siding?

While DIY installation is possible for vinyl siding, fiber cement is best installed by professionals due to its weight and the specialized tools required. Improper installation can void warranties.