Hardie Board vs Vinyl Siding Cost A Detailed Comparison

Hardie board vs vinyl siding cost: Choosing the right siding for your home is a big decision, impacting both your wallet and your home’s curb appeal. This comparison dives deep into the initial costs, long-term expenses, and material properties of Hardie board and vinyl siding, helping you make an informed choice that fits your budget and lifestyle. We’ll break down everything from installation costs and maintenance needs to environmental impact and aesthetic considerations, so you can confidently select the best siding for your project.

Understanding the differences between Hardie board and vinyl siding goes beyond just the initial price tag. Factors like durability, lifespan, maintenance requirements, and even the environmental impact all play crucial roles in determining the overall cost of ownership. This guide will equip you with the knowledge to weigh these factors and make a smart decision that aligns with your priorities.

Initial Cost Comparison

Source: homeimprovementcents.com

Choosing between Hardie board and vinyl siding often comes down to budget. While both offer weather protection, their initial costs differ significantly, influenced by factors like material quality and installation complexity. Let’s break down the price differences to help you make an informed decision.

Average Cost Per Square Foot

The cost of siding varies greatly depending on the material, its quality, and your location. Generally, Hardie board is more expensive than vinyl siding upfront. The following table provides average cost estimates per square foot in USD. Keep in mind that these are estimates and actual costs can vary based on your region and specific project needs.

| Siding Type | Low-Quality Cost | Medium-Quality Cost | High-Quality Cost |

|---|---|---|---|

| Hardie Board | $3 – $5 | $6 – $8 | $9 – $12 |

| Vinyl Siding | $2 – $4 | $4 – $6 | $6 – $8 |

Factors Influencing Initial Cost

Several factors contribute to the price differences between Hardie board and vinyl siding. Understanding these factors will give you a better understanding of the total cost.

The initial cost variation is primarily influenced by:

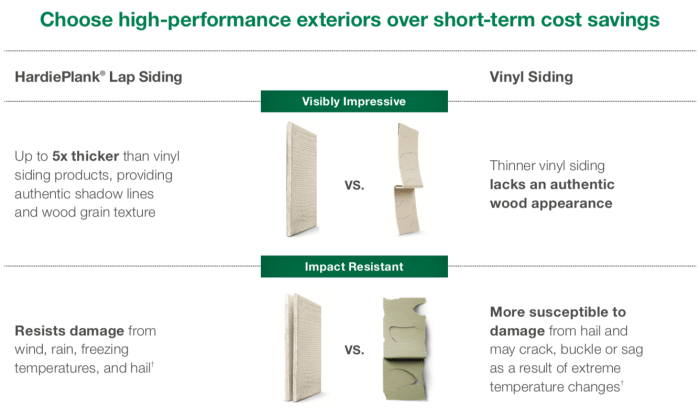

- Material Thickness: Thicker materials generally cost more. High-quality Hardie board is thicker and more durable than low-quality vinyl siding, leading to a higher price tag.

- Color Choices: Custom colors and finishes often add to the overall cost. Solid colors are typically less expensive than more complex patterns or textures.

- Installation Complexity: The complexity of your home’s exterior can affect labor costs. Homes with intricate designs or multiple angles may require more time and expertise, thus increasing the installation cost.

- Regional Pricing: Material and labor costs vary depending on your location. Areas with high demand or limited supply may see higher prices.

Installation Cost Breakdown

The installation cost includes both labor and materials. Labor costs are heavily influenced by the complexity of the job and the installer’s experience. Material costs, as discussed earlier, vary based on quality and choice.

| Cost Component | Hardie Board (per sq ft) | Vinyl Siding (per sq ft) |

|---|---|---|

| Materials | $3 – $12 | $2 – $8 |

| Labor | $2 – $5 | $1 – $3 |

| Total (Estimate) | $5 – $17 | $3 – $11 |

Long-Term Cost Considerations

Source: citycountry.ca

Choosing between Hardie board and vinyl siding involves more than just the upfront price; long-term costs, including maintenance and potential repairs, significantly impact the overall expense. Understanding the lifespan and maintenance needs of each material is crucial for making an informed decision. This section delves into these long-term financial implications to help you weigh your options effectively.

Both Hardie board and vinyl siding offer different lifespans and maintenance requirements, leading to varying long-term costs. While vinyl siding is generally less expensive initially, Hardie board’s superior durability might translate to lower costs over the long run.

Lifespan and Maintenance Requirements

The longevity and maintenance frequency of each siding type directly impact the total cost of ownership over time. Regular maintenance can extend the life of your siding and prevent costly repairs down the line.

- Hardie board: Typically boasts a lifespan of 30-50 years or more with proper maintenance. This involves occasional power washing to remove dirt and grime, and prompt repair of any damaged panels. Repairs are generally straightforward but can be more labor-intensive than vinyl repairs.

- Vinyl siding: Generally lasts 20-30 years, although some lower-quality vinyl can fail sooner. Maintenance is relatively low; usually just an occasional rinsing with a hose. However, vinyl is more prone to damage from impact and extreme weather conditions, necessitating more frequent, albeit simpler, repairs.

Repair and Replacement Costs (20-Year Period), Hardie board vs vinyl siding cost

Predicting exact repair costs is difficult, as they depend on factors like the extent of damage, labor costs in your area, and the specific issues encountered. However, we can compare the likely types and costs of repairs for both siding types over 20 years.

| Issue | Hardie Board (Estimated Cost) | Vinyl Siding (Estimated Cost) |

|---|---|---|

| Minor damage repair (e.g., small crack, dent) | $50-$200 per repair | $25-$100 per repair |

| Section replacement due to storm damage | $500-$1500 per section | $300-$1000 per section |

| Full siding replacement | $10,000-$20,000 (depending on house size) | $6,000-$15,000 (depending on house size) |

Note: These are estimates and actual costs can vary significantly based on location, contractor, and extent of damage. Always obtain multiple quotes before undertaking any repairs or replacements.

Hidden Costs

Beyond the obvious repair costs, hidden expenses can arise unexpectedly with both siding types. Being aware of these potential costs can help you budget more accurately.

- Hardie board: While durable, Hardie board can be susceptible to moisture damage if not properly installed or maintained. This can lead to rot and require extensive, costly repairs. Additionally, repainting every 5-10 years may be necessary to maintain the appearance and protect the fiber cement from the elements. This adds to the long-term cost.

- Vinyl siding: While generally low-maintenance, vinyl siding can be easily scratched or dented, especially lighter colors. Replacing damaged panels can become frequent, particularly if you have pets or active children. Also, extreme temperature fluctuations can cause warping or cracking in lower-quality vinyl siding. Professional cleaning may be needed to remove stubborn stains or mildew, adding another cost element.

Material Properties and Durability

Source: elitehomeexteriorsnw.com

Choosing between Hardie board and vinyl siding involves understanding their inherent material properties and how these affect their longevity and maintenance needs. Both offer distinct advantages and disadvantages, making the “best” choice highly dependent on your specific climate, budget, and aesthetic preferences. Let’s delve into a detailed comparison.

Impact Resistance, Weathering, and Pest Infestation

Hardie board and vinyl siding react differently to the challenges posed by impacts, weather, and pests. Understanding these differences is crucial for predicting long-term maintenance costs.

| Property | Hardie Board (Fiber Cement) | Vinyl Siding |

|---|---|---|

| Impact Resistance | High resistance to dents and damage from impacts; however, it can crack under significant force. | Relatively low resistance to impacts; dents and cracks are more easily sustained. |

| Wind Resistance | Excellent wind resistance; designed to withstand high winds. | Good wind resistance, but can be damaged by very strong winds, especially if improperly installed. |

| Rain and Snow Resistance | Highly resistant to water damage due to its non-porous nature. | Resistant to water damage, provided it’s properly installed and maintained; some water absorption can occur. |

| Pest Infestation | Resistant to insect infestation and rot due to its composition. | Can be susceptible to insect damage, particularly in areas with high humidity. Termites, for instance, can cause damage to vinyl siding, especially older types. |

Fire Resistance and Energy Efficiency

Fire safety and energy efficiency are critical considerations in exterior cladding. Hardie board and vinyl siding demonstrate different performance levels in these areas.

Hardie board, being a cement-based composite, is inherently fire-resistant. It carries a Class A fire rating, the highest rating available, meaning it’s unlikely to contribute to the spread of fire. This significantly reduces the risk of fire damage to your home and may even result in lower insurance premiums. However, it’s important to note that even fire-resistant materials can be damaged by intense heat.

Vinyl siding, on the other hand, is flammable. While it doesn’t readily ignite, it will melt and burn under sustained exposure to flames. Its fire rating is generally Class C, indicating it offers less fire protection than Hardie board.

In terms of energy efficiency, both materials contribute to a home’s insulation. However, Hardie board often has a slight edge, due to its denser composition. This leads to slightly better thermal resistance compared to vinyl siding. The difference may not be dramatic in most cases, but it can contribute to modest long-term savings on energy bills. The precise energy savings depend on factors such as climate, insulation levels in the walls, and overall home design. For example, a home in a cold climate might see a more noticeable difference than one in a milder climate.

Aesthetic Considerations

The visual appeal of your home’s exterior is a key factor in choosing siding. Hardie board and vinyl siding offer different aesthetic qualities.

The following points highlight key differences in texture, color, and overall appearance:

- Texture: Hardie board offers a more textured, wood-like appearance. It can mimic the look of real wood clapboard or shingles. Vinyl siding typically has a smoother, more uniform texture, although some manufacturers offer textured options to simulate wood grain or other materials.

- Color Options: Both materials are available in a wide range of colors, but Hardie board’s color is often integrated into the material itself, making it more resistant to fading compared to painted vinyl siding which can fade over time, especially with prolonged exposure to UV radiation.

- Overall Appearance: Hardie board tends to project a more sophisticated, natural look, while vinyl siding can appear more uniform and sometimes less visually interesting, though textured vinyl options can help mitigate this.

Installation Process and Time

Choosing between Hardie board and vinyl siding involves considering not only material costs but also the labor involved in installation. The installation process, including time and skill requirements, significantly impacts the overall project cost. A faster, simpler installation translates to lower labor expenses, while complex installations necessitate more skilled labor and therefore, higher costs.

The installation time for both Hardie board and vinyl siding varies depending on factors such as house size, complexity of the design (e.g., many dormers, intricate trim), and the experience level of the installers. However, we can provide a general comparison to illustrate the differences.

Installation Time and Labor Hours Comparison

The following table provides estimated installation times for an average-sized single-family home (approximately 2,000 square feet of siding). These are estimates, and actual times can vary significantly.

| Siding Type | Estimated Installation Time | Estimated Labor Hours |

|---|---|---|

| Hardie Board | 5-7 days | 80-112 hours |

| Vinyl Siding | 3-5 days | 48-80 hours |

Specialized Tools and Skills Required

Both Hardie board and vinyl siding installations require specific tools and skills. The level of expertise needed differs significantly, influencing the choice between DIY and professional installation.

- Hardie Board: Requires more specialized tools and skills due to its harder, more rigid nature. Installers need experience with cutting and handling cement-based materials, precise measuring and cutting to avoid cracking, and knowledge of proper fastening techniques to prevent damage. Necessary tools include circular saws with fine-tooth blades, specialized cutting tools for intricate cuts, and impact drivers for proper fastening. Experience with working at heights and understanding of building codes is also crucial.

- Vinyl Siding: Generally requires less specialized skill and tools. While precision is still important, vinyl is more forgiving than Hardie board. Common tools include measuring tapes, utility knives, levels, and jigsaws. However, proper installation techniques are still essential to ensure a watertight and aesthetically pleasing finish. Experience with working with interlocking systems and understanding of expansion and contraction properties of vinyl is beneficial.

DIY vs. Professional Installation

The decision to DIY or hire professionals impacts both the final cost and the quality of the installation. Each approach has its advantages and disadvantages.

- Hardie Board: DIY installation is generally not recommended for Hardie board siding due to the specialized skills and tools required. Improper installation can lead to cracking, water damage, and compromised durability, negating any cost savings. Professional installation ensures proper techniques are used, leading to a longer-lasting and more aesthetically pleasing result. While more expensive upfront, it minimizes the risk of costly repairs later.

- Vinyl Siding: Vinyl siding is often considered more DIY-friendly due to its easier handling and installation. However, even with vinyl, improper installation can lead to issues like gaps, water leaks, and damage. While DIY can save money on labor costs, professional installation ensures a higher-quality result, especially for complex house designs. The cost savings from DIY might be offset by potential repair costs if problems arise.

Environmental Impact

Source: cdn-website.com

Choosing between Hardie board and vinyl siding involves considering more than just upfront costs; the environmental impact of each material throughout its lifecycle is a significant factor. From manufacturing and transportation to disposal and potential for recycling, both options have distinct environmental footprints. Let’s examine these aspects to help you make an informed decision.

Both Hardie board (fiber cement) and vinyl siding have environmental impacts stemming from their production, transportation, and disposal. However, the nature and magnitude of these impacts differ considerably.

Manufacturing Processes and Associated Emissions

Hardie board manufacturing uses cement, which has a high carbon footprint due to the energy-intensive process of cement production. The process also involves the mining and transportation of raw materials, further contributing to emissions. Vinyl siding, on the other hand, is produced from petroleum-based PVC (polyvinyl chloride), a non-renewable resource. PVC production requires significant energy and releases harmful byproducts like dioxins during manufacturing. While some manufacturers are working towards more sustainable PVC production methods, the overall environmental impact remains substantial.

Transportation and Distribution

The transportation of both materials contributes to greenhouse gas emissions. The weight and bulk of Hardie board generally mean higher transportation costs and a larger carbon footprint compared to lighter vinyl siding. However, the distance materials travel to reach the construction site will heavily influence the total environmental impact of transportation. Local sourcing of either material can significantly reduce the transportation-related environmental impact.

Environmental Footprint Comparison

| Factor | Hardie Board | Vinyl Siding |

|---|---|---|

| Manufacturing Emissions (CO2 equivalent) | High (due to cement production) | High (due to PVC production and energy consumption) |

| Transportation Emissions | Moderately High (due to weight) | Moderately Low (due to lighter weight) |

| Recyclability | Limited; some regional programs exist. | Limited; specialized recycling facilities are needed. |

| Disposal Impact | Landfill space usage; potential for asbestos-containing versions in older homes. | Landfill space usage; potential for leaching of harmful chemicals. |

Recyclability and Sustainability

Recycling options for both Hardie board and vinyl siding are limited. While some regions have programs for recycling fiber cement, they are not widespread. Vinyl siding recycling is even more challenging due to the complexity of separating PVC from other materials. The lack of robust recycling infrastructure for both materials contributes to landfill waste. The potential for reuse is also limited; reusing Hardie board is challenging due to its fragility and potential damage during removal. Vinyl siding is similarly difficult to reuse effectively.

Long-Term Environmental Costs

The long-term environmental costs associated with Hardie board and vinyl siding extend beyond initial manufacturing and disposal. Let’s examine some key differences.

- Energy Consumption: Both materials require energy for manufacturing, but the energy intensity differs significantly. Cement production for Hardie board is generally more energy-intensive than PVC production for vinyl siding, although this can vary depending on manufacturing processes and energy sources used.

- Carbon Emissions: The carbon footprint of Hardie board is largely driven by cement production, while vinyl siding’s carbon footprint is tied to petroleum extraction and PVC manufacturing. Both contribute significantly to greenhouse gas emissions.

- Leaching and Degradation: Vinyl siding can leach harmful chemicals into the soil and groundwater over its lifespan. Hardie board, while generally inert, can release small amounts of alkaline compounds over time. The extent of leaching depends on factors like exposure to weather and soil conditions.

- Durability and Replacement: The longer lifespan of Hardie board can reduce the overall environmental impact compared to vinyl siding which may need replacement sooner, thereby leading to increased manufacturing, transportation, and disposal impacts over time.

Ultimate Conclusion: Hardie Board Vs Vinyl Siding Cost

Ultimately, the “best” siding—Hardie board or vinyl—depends entirely on your individual needs and priorities. While Hardie board often commands a higher upfront cost, its superior durability and longevity can translate to long-term savings. Vinyl siding, on the other hand, offers a more budget-friendly initial investment but may require more frequent repairs and replacements over time. By carefully considering the factors discussed—initial cost, long-term maintenance, durability, and environmental impact—you can confidently choose the siding option that best balances your budget with your desired aesthetic and performance expectations.

Essential Questionnaire

What about insurance considerations? Does one siding type affect home insurance premiums?

Yes, some insurance companies may offer slight discounts for homes with more fire-resistant siding like Hardie board. It’s best to check with your insurer for specifics.

Can I install either siding myself?

While both are *possible* DIY projects, professional installation is generally recommended, especially for Hardie board, due to its more complex installation process. DIY can save on labor costs but risks improper installation leading to future problems.

How does climate affect the choice between Hardie board and vinyl siding?

Extreme weather conditions might favor Hardie board’s superior durability. However, vinyl’s flexibility can be advantageous in areas prone to severe temperature fluctuations. Consider your local climate when making your decision.

What are the warranty options for each siding type?

Both Hardie board and vinyl siding manufacturers offer warranties, but the specifics (length, coverage) vary by product and manufacturer. Always review the warranty details before purchasing.