How Much Does Hardie Siding Cost?

How much does Hardie siding cost? That’s a question many homeowners ask before embarking on a home exterior renovation. The price depends on a lot of things, from the size of your house and the complexity of the job to the specific type of Hardie siding you choose and where you live. We’ll break down all the factors influencing the cost, helping you get a realistic estimate for your project.

This guide will walk you through the various cost components, including materials (like fiber cement planks, trim, and fasteners), labor (professional installation versus DIY), and regional price variations. We’ll also explore different Hardie siding options and their price ranges, helping you make informed decisions that fit your budget.

Factors Influencing Hardie Siding Cost

Source: sidinggroup.com

Getting Hardie siding installed can be a significant investment, and the final price tag depends on a number of interconnected factors. Understanding these factors will help you budget effectively and make informed decisions during the planning process. This section breaks down the key elements influencing the overall cost.

Material Costs

The base cost of Hardie siding varies based on several material characteristics. Different types of fiber cement boards offer varying degrees of durability and aesthetic appeal, directly impacting the price. Color choices also play a role, with some colors and finishes costing more than others. Finally, the texture of the siding – whether it mimics wood grain, stucco, or a smooth finish – influences the manufacturing process and consequently the cost.

| Factor | Description | Impact on Cost | Example |

|---|---|---|---|

| Fiber Cement Board Type | Different thicknesses and formulations offer varying durability and performance. | Thicker, more durable boards cost more. | Standard lap siding is generally less expensive than premium options like panel systems. |

| Color | Custom colors and specialized finishes (e.g., deep colors requiring more pigment) often increase the cost. | Popular neutral colors are typically less expensive than custom blends. | A standard gray might cost less than a deep, custom-mixed burgundy. |

| Texture | Textured surfaces (e.g., wood grain) generally involve more complex manufacturing processes. | Smooth finishes are usually less expensive than textured options. | A smooth finish will generally be cheaper than a cedar-shake-style texture. |

Labor Costs

Labor costs are a substantial part of the overall project expense. The complexity of your home’s design significantly affects the time and skill required for installation. Factors like the number of corners, windows, and intricate architectural details all influence labor hours. Additionally, regional differences in labor rates affect the final cost. Highly skilled installers in high-demand areas will naturally command higher wages.

Regional Variations, How much does Hardie Siding cost

The cost of materials and labor can fluctuate significantly across different regions. Transportation costs, local supply and demand, and prevailing wage rates all contribute to these variations. For example, Hardie siding might cost more in areas with limited access to suppliers or a high concentration of construction projects.

House Size and Complexity

The size and complexity of your house directly influence the amount of siding needed and the time required for installation. A small, simple ranch-style home will naturally require less material and labor than a large, multi-gabled Victorian.

Example: A 1,500 sq ft ranch house might require approximately 100-150 squares of siding (a square is 100 square feet), while a 4,000 sq ft Victorian with intricate detailing could easily need 300-400 squares or more. The increased material quantity and more complex installation for the Victorian will significantly drive up the overall cost.

Installation Methods

Different installation methods can impact the overall cost. While the most common method involves nailing the siding directly to the sheathing, alternative methods exist. These might include using furring strips to create a more even surface or specialized fastening systems. While some methods might provide superior performance or aesthetics, they usually add to the overall project expense. The added cost is justified if the chosen method offers long-term benefits.

Material Costs: How Much Does Hardie Siding Cost

Let’s get into the nitty-gritty of Hardie siding costs – the materials themselves. The price you pay will depend heavily on the specific product you choose, its finish, and the quantity needed for your project. Remember, these are estimates, and actual costs can vary based on location, supplier, and current market conditions.

Understanding the cost breakdown of the different Hardie siding products is key to budgeting your project accurately. Factors such as the type of siding (lap, panel, shingle, etc.), the material composition (fiber cement), and the finish (smooth, textured, etc.) all contribute to the final price.

Hardie Siding Product Price Ranges

The following price ranges are per square (100 square feet) and are estimates. Always get quotes from your local supplier for the most accurate pricing.

- HardiePlank Lap Siding: $1.50 – $4.00 per square foot (depending on profile and finish).

- HardiePanel Vertical Siding: $1.75 – $4.50 per square foot (depending on profile and finish).

- HardieShingle Siding: $2.00 – $5.00 per square foot (depending on profile and finish).

- HardieTrim & Accessories: $2.50 – $6.00 per linear foot (depending on style and profile).

Premium Color and Texture Cost Implications

Choosing premium colors or textures will generally increase the cost of your Hardie siding. These options often involve specialized manufacturing processes or unique pigments, resulting in a higher price point.

| Color/Texture | Cost Increase (Approximate Percentage) | Example |

|---|---|---|

| Standard Colors | 0-10% | Classic white or beige |

| Premium Colors | 10-25% | Deep blues, reds, or custom blends |

| Textured Finishes (e.g., cedar-shake) | 15-30% | A finish designed to mimic natural wood |

Accessory Costs

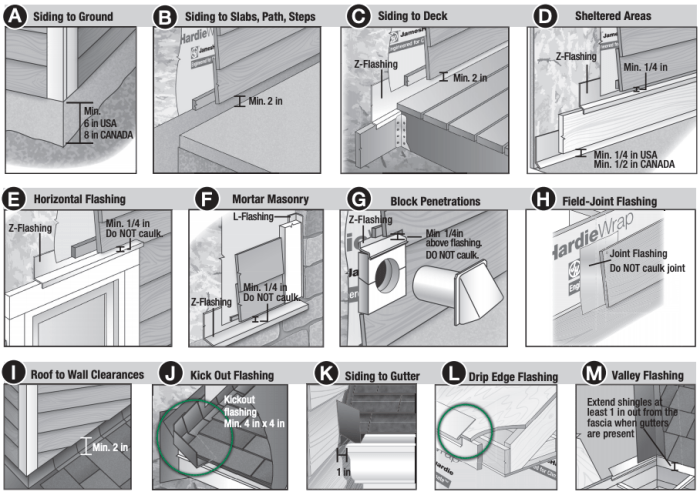

Don’t forget about the additional costs associated with trim, flashing, and fasteners. These are essential components for a proper and long-lasting installation. The quantity required will depend on the size and complexity of your home.

Let’s consider a medium-sized home (approximately 2,000 square feet of siding). A reasonable estimate for accessories might look like this:

- Trim: $1,000 – $2,000 (depending on the amount of trim used)

- Flashing: $500 – $1,000 (to protect against water damage around windows, doors, and other openings)

- Fasteners: $200 – $500 (nails, screws, etc.)

These costs are estimates and can vary significantly depending on the specific design of your home and the materials chosen.

Labor Costs and Installation

Source: octanecdn.com

Getting Hardie siding installed involves more than just the materials; labor costs are a significant portion of the overall project expense. Understanding these costs, both upfront and hidden, is crucial for accurate budgeting and avoiding unpleasant surprises. This section will break down the typical costs associated with professional installation and compare it to the DIY route.

Hourly Rates for Professional Installers

Hourly rates for experienced Hardie siding installers vary considerably depending on location, experience level, and the complexity of the job. In many parts of the country, you can expect to pay anywhere from $40 to $80 per hour per installer. However, this is just a broad range. Coastal areas or regions with high construction costs, such as parts of California or the Northeast, might see rates closer to the higher end, even exceeding $100 per hour. Conversely, more rural areas might have lower rates, potentially starting around $30 per hour. The size and experience of the installation company also influences pricing; smaller, local companies may be more affordable than large national firms. It’s always wise to get multiple quotes to compare pricing and ensure you’re getting a fair deal.

Potential Hidden Labor Costs

Beyond the hourly rate, several often-overlooked costs can significantly impact the final labor bill. These “hidden” costs can catch homeowners off guard if not properly addressed upfront. Examples include:

- Waste removal: Disposing of old siding and construction debris can add hundreds of dollars to the project. This cost isn’t always included in the initial quote.

- Site preparation: This might involve tasks like removing existing siding, repairing damaged areas of the house, or preparing the surface for installation. These preparatory steps can consume significant labor hours.

- Permitting fees: While not strictly labor, securing necessary permits is a crucial step, and delays or additional fees can arise if not handled correctly.

- Unexpected repairs: During installation, unforeseen problems such as rotted wood or damaged sheathing might be discovered, leading to additional labor costs for repairs.

- Travel time: For installers traveling a significant distance, travel time might be factored into the total labor cost.

To avoid these hidden costs, use this checklist:

- Get a detailed, itemized quote: Don’t settle for a single lump-sum price. Ask for a breakdown of labor costs, materials, and any other anticipated expenses.

- Clarify waste disposal: Specifically ask if waste removal is included in the quote. If not, get a separate estimate for this service.

- Discuss site preparation: Ensure the quote addresses all necessary site preparation tasks. Ask for clarification on what’s included and what might require extra charges.

- Inquire about permits: Confirm whether the installer will handle permitting or if this is your responsibility.

- Ask about contingency plans: Discuss how unexpected issues (e.g., rotted wood) will be handled and if there are contingency plans for additional costs.

Professional Installation vs. DIY

Hiring a professional offers the advantage of expertise, ensuring proper installation, a warranty on the labor, and potentially faster completion. However, it comes with a higher upfront cost. DIY installation can save money on labor, but it requires significant time, skills, and the purchase of specialized tools. The risk of improper installation, leading to potential damage or voiding warranties, is a significant consideration. A homeowner skilled in construction and with the necessary tools might save considerably, but for most homeowners, the risks and time commitment outweigh the potential savings. A realistic assessment of your skills and available time is crucial before choosing the DIY route. Consider the potential cost of mistakes and the time value of your labor when making your decision. For example, a DIY project that takes a homeowner three weekends could cost them more in lost income than paying a professional.

Regional Price Variations

Hardie siding costs aren’t uniform across the United States. Several factors, including geographic location, local regulations, and market conditions, contribute to significant price differences between regions. Understanding these variations is crucial for accurate budgeting and project planning.

Geographic location plays a major role in determining the final cost of your Hardie siding project. Transportation costs, material availability, and local labor markets all influence pricing. Areas with high concentrations of construction activity may experience higher demand and, consequently, higher prices. Conversely, more remote locations might see higher costs due to transportation fees for materials.

Geographic Cost Variations

Imagine a map of the continental US. Generally, you’d see higher costs along the coasts, particularly in densely populated areas like California, New York, and Florida. These regions often have higher labor costs and greater demand, driving up the overall price. In contrast, the Midwest and some Southern states might offer slightly lower prices due to lower labor costs and potentially less competition among contractors. The Rocky Mountain region and parts of the Southwest could show a mixed bag, with some areas experiencing higher costs due to remoteness and transportation challenges, while others see more moderate pricing. This is a general overview; specific cities and towns within these regions will have their micro-economic factors influencing price.

Impact of Local Regulations and Building Codes

Local regulations and building codes significantly impact the cost of Hardie siding installation. For example, some areas may require specific types of installation methods or additional permits, increasing both labor and administrative expenses. A city mandating specialized fire-resistant materials, for instance, could add to the overall project cost. Similarly, strict environmental regulations regarding waste disposal during construction can add unforeseen expenses. In contrast, areas with more lenient regulations might lead to lower overall costs. It’s essential to check with local authorities to understand specific requirements and their associated costs before starting your project.

Urban vs. Rural Cost Comparison

Urban areas typically see higher Hardie siding costs than rural areas. The higher density of construction projects in cities often leads to greater competition among contractors, potentially pushing up labor rates. Furthermore, the cost of land and materials is usually higher in urban centers due to increased demand. In contrast, rural areas may offer lower labor costs and potentially more competitive material pricing. However, this difference might be offset by the added costs of transporting materials over longer distances. The availability of skilled labor also plays a role; finding qualified installers might be easier and potentially cheaper in a larger city, while rural areas might have fewer options, potentially increasing costs.

Estimating the Total Cost

Getting an accurate estimate for Hardie siding installation is crucial for budgeting your home renovation. Several factors contribute to the final price, and understanding how to calculate them will help you avoid unexpected costs. This section will guide you through a step-by-step process, using examples and tools to help you create a realistic budget.

A Step-by-Step Guide to Estimating Total Cost

Accurately estimating the total cost involves breaking down the project into its constituent parts. This allows for a more precise understanding of where your money is going and helps avoid overspending.

- Measure your home’s exterior: Carefully measure the total square footage of your home’s exterior walls that will receive Hardie siding. Remember to account for windows, doors, and other features that will reduce the actual siding area. For example, a house with 1500 square feet of wall space might only require 1200 square feet of siding after accounting for openings.

- Determine the type of Hardie siding: Different Hardie siding products have varying prices. Lap siding, vertical siding, and shingles all come with different price tags. Research the costs of your chosen material per square foot from local suppliers. This price often varies depending on the chosen color and texture.

- Calculate material costs: Multiply the square footage of your siding needs by the price per square foot of your chosen Hardie siding. Add any extra materials, such as trim, flashing, and fasteners, to this figure. For example, if you need 1200 square feet of siding at $5 per square foot, the material cost would be $6000. Remember to add a 10-15% buffer for waste and unexpected issues.

- Estimate labor costs: Labor costs vary significantly by region and contractor. Get at least three quotes from reputable contractors. Labor costs are typically quoted per square foot and can range from $2 to $8 or more, depending on complexity and location. For our 1200 square foot example, if the labor cost is $4 per square foot, the labor cost would be $4800.

- Include additional expenses: Account for permits, waste removal, and any other potential expenses. Permits can range from $100 to $500 or more depending on your location and the project scope. Waste removal might cost around $200-$500. These costs often get overlooked but are essential to a complete budget.

- Calculate the total cost: Add together your material costs, labor costs, and additional expenses to arrive at a final estimated cost. In our example, the total estimated cost would be $6000 (materials) + $4800 (labor) + $300 (permits) + $300 (waste removal) = $11,400.

Utilizing Online Cost Calculators and Other Tools

Many online resources provide cost calculators to estimate Hardie siding installation. These tools often require you to input details like square footage, siding type, and location. While convenient, remember these are estimates, and it’s vital to confirm with local contractors for accurate pricing. Always compare multiple calculator results and cross-reference with contractor quotes. Remember to check the reputation and reviews of the website providing the calculator before relying on its results.

Sample Budget for Hardie Siding Installation

This table provides a sample budget for a typical home renovation project involving Hardie siding. Remember that these figures are estimates and can vary widely depending on the specifics of your project.

| Expense Category | Estimated Cost |

|---|---|

| Materials (Hardie Siding, Trim, Fasteners) | $6000 |

| Labor | $4800 |

| Permits | $300 |

| Waste Removal | $300 |

| Total Estimated Cost | $11,400 |

Outcome Summary

Source: dhexteriors.com

So, how much *does* Hardie siding cost? Ultimately, the answer is: it depends. However, by understanding the factors we’ve discussed – material choices, labor costs, regional differences, and your home’s specifics – you can develop a much more accurate estimate. Remember to factor in potential hidden costs and get multiple quotes from reputable contractors. With careful planning, you can achieve your dream home exterior without breaking the bank.

FAQ Summary

Can I install Hardie siding myself?

While DIY is possible, it’s generally recommended to hire professionals. Professional installation ensures proper techniques, leading to a longer-lasting, more aesthetically pleasing result, and often avoids costly mistakes.

What’s the lifespan of Hardie siding?

Hardie siding is known for its durability and longevity. With proper installation and maintenance, it can last for 30 years or more.

Does Hardie siding require much maintenance?

Hardie siding requires minimal maintenance. Occasional cleaning with soap and water is usually sufficient.

Is Hardie siding environmentally friendly?

Yes, Hardie siding is made from sustainable materials and is a relatively environmentally friendly option compared to some other siding materials.

Are there financing options available for Hardie siding installation?

Many contractors offer financing options or can connect you with lenders specializing in home improvement projects. Check with your contractor for details.